Связаться с нашей командой

- 4627

Introduction

Bagasse is the by-product of sugar cane processing, gaining lately in food packaging due to its sustainability and environment friendliness. The use of safe materials in hot food applications helps avoid health hazards and retains the quality of foodstuffs. This paper explores the safety of bagasse products in hot food applications based on the following:

• Unique Properties and Benefits of the By-product

• Safety research and observance of the laws concerning food

• Conservation drive and consumer culture for sustainable packaging

Understanding Bagasse and Its Properties

Bagasse Defined

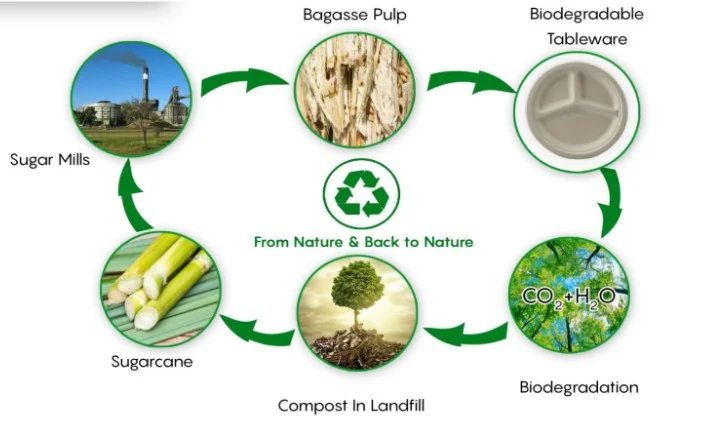

Bagasse is the fibrous material left when sugar cane is processed to extract juice. It was once regarded as waste, but it has been found a new use in green packaging.

Sustainable Practices and Bagasse

Using bagasse has greatly played a role in sustainable practices. Instead of wasting this agricultural by-product, it makes useful items such as containers of food and tableware. For this reason, not only does it reduce waste but also reduces reliance on non-renewable sources such as plastics and Styrofoam. Further information about how bagasse is being used for sustainable packaging can be accessed on the sugarcane fiber packaging guide.

Grease-Proof Characteristics

The bagasse also plays an important role in the food containers in withstanding the grease. Traditionally, bags and Styrofoam containers can easily allow grease penetrate right through to compromise the integrity of the container. However, bagasse is naturally grease-proof, which is excellent for holding greasy or oily foods without leakages.

Advantages Of Traditional Materials

• Eco-Friendly: Unlike plastic, bagasse is biodegradable and compostable.

• Durability: Bagasse containers are rigid, and not easy to be punctured.

• Grease Resistance: Better than most conventional materials that bleed

• Microwave-Safe: Its concentration does not release harmful chemicals within the body during heating food.

Temperature Tolerance

Products of bagasse withstood temperatures up to 120°C (about 248°F). This allows for the use in these products in effectively using it when served hot without losing its integrity. Under high heat conditions, the performance of bagasse made it a trusted one for several food service operations such as catering and take-out services where ensuring food temperature is at a point that should not be compromised.

Understanding these properties highlights why bagasse packaging stands out as a viable alternative to traditional materials. The combination of sustainability, durability, and heat resistance makes it an excellent choice for modern food packaging needs. Moreover, advancements in molded pulp products for sustainable packaging have further enhanced the versatility and application of bagasse in various sectors.

Safety Assessment for Hot Food Applications with Bagasse Products

Food contact safety is required. Testing of products produced from bagasse is tested for thermally enduring. Checking also on substances that may leach when in contact with food.

Key testing requirements include:

• Migration tests: It should indicate if there is a transfer of chemical, to food, at safe levels from bagasse.

• Thermal stability tests: Determines if the material, when exposed to heat, would degrade or leach at high temperatures

• Grease resistance tests: Indicates if the product is resistant to oily or greasy foods and can withstand the food influences without breaking down.

Compliance by the FDA in the United States and European Union directives on the case of bagasse products means that the products meet the requirements of safety relative to use with hot foods. It sets permissible contaminant levels and sets protocol testing so as to ensure consumer safety.

Microwave-Safe Properties of Bagasse Products

Bagasse products are heat-resistant and microwave-safe; they can very well be very useful for food applications. Being able to sustain a temperature of as high as 120°C, roughly equivalent to 248°F, you can reheat food without compromising the structure or safety of the container.

Microwave-safe properties include:

• Heat endurance: Maintains the rigidity structure even when heated long enough in a microwave.

• Non-toxicity under heat: No toxic chemicals are released when heated in the microwave.

• Uniform heating: The product heats evenly, eliminating hot spots that could result in burns or overcooking.

When it comes to bagasse products, you have confidence that the items will meet the essential safety standards for applications of hot food. They offer a safer, sustainable alternative without compromising on performance and safety.

Environmental Impact and Consumer Demand for Bagasse Products

The most relevant advantage that bagasse presents is on the environmental level. Bagasse products typically biodegrade in industrial composting conditions within a period of 1 to 6 months. It has been projected that non-biodegradable products such as plastic and Styrofoam will last hundreds of years in the environment.

With better environmental awareness, consumers tend to give more importance to green packaging. Thus they are opting for greener options. Food service and retail industries are not different in this context. Bagasse products do qualify on their part as they can be used as compost instead of landfilling or adding to the carbon footprint

Breakdown Time:

• Bagasse: 1-6 months in industrial composting

• Plastic: Over 1,000 years

• Styrofoam: Indefinite

Growing demand for sustainable products draws attention to alternative substitutes like bagasse. A choice of biodegradable materials is seen to directly contribute towards reduced environmental pollution and to one where a circular economy is promoted.

From its environmental-friendliness, the product appeals to businesses and consumers as keen to minimize adverse environmental impacts while ensuring their application of hot food is safe and quality.

Conclusion

Great benefits of bagasse products in relation to packaging hot food applications lie in being rugged and heat resistant, in addition to their ecological advantages. They can also endure as high as 120°C heat so the structure may not be damaged by the condition of hot exposure.

The future seems bright for bagasse products, especially when consumers seek sustainable packaging materials. Its biodegradable and compostable nature gives it a big edge in being substituted as opposed to the traditional materials being used, such as Styrofoam.

Is bagasse safe for hot food applications? Yes, bagasse is a sustainable and sound resource for the food service industry.

FAQs (Frequently Asked Questions)

1. What is bagasse and how is it produced?

Bagasse is a fibrous by-product obtained from the processing of sugar cane. It plays a significant role in sustainable practices as it can be used to create biodegradable packaging materials.

2. Are bagasse products safe for hot food applications?

Yes, bagasse products are considered safe for hot food applications. They have been tested for compliance with safety standards and can withstand temperatures up to 120°C without compromising their integrity.

3. What are the grease-proof characteristics of bagasse packaging?

Bagasse packaging possesses excellent grease resistance, making it suitable for containing oily or greasy foods. This characteristic helps maintain the quality of the food while preventing leakage.

4. Can bagasse products be used in microwaves?

Yes, many bagasse products are microwave-safe, allowing consumers to heat their food without worrying about harmful chemicals leaching into the food or the container degrading under high heat conditions.

© 2024 , Goldleaf ,

Все права защищены.

Made & Managed by Lightlink Solutions